The next Generation of Sheet Metal Forming

POSSIBILITIES POWERED BY LASERS

Our supporters and collaborators

Laser Automation for Manufacturing

AutoShape revolutionizes sheet metal manufacturing with a patented laser forming platform that replaces multiple traditional machines.

We design and build 4-in-1 machines that unify cutting, forming, engraving, and automated quality assessment — delivering cleaner, faster, and more cost-efficient production with a significantly smaller footprint.

Our technology reduces waste, accelerates development cycles, and enables seamless changeovers straight from CAD. This flexibility and sustainability align with Europe’s ambition to reinforce industrial competitiveness and technological sovereignty.

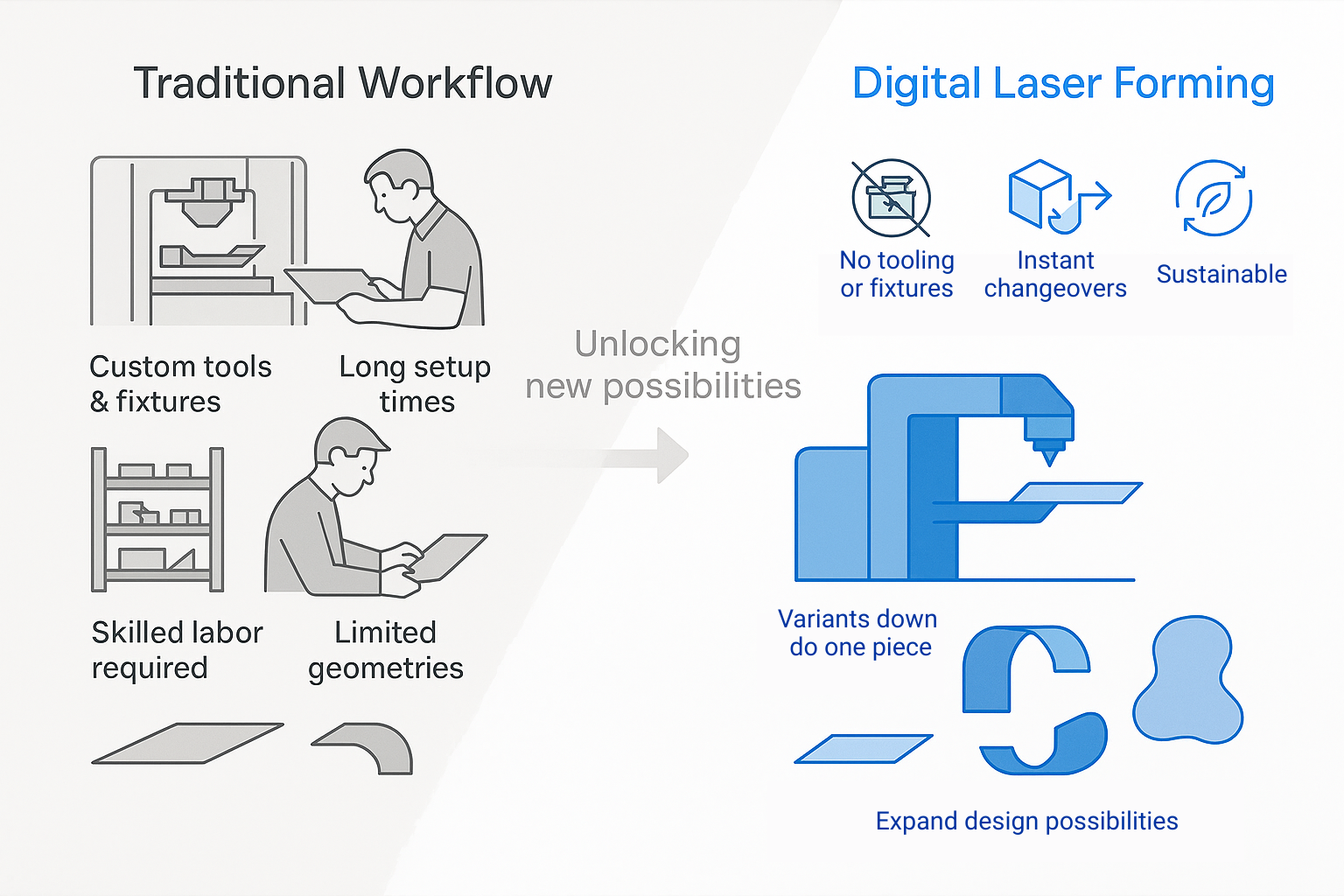

Challenges for customers

Manufacturers are expected to deliver more variety, higher quality, and faster results than ever. Yet traditional forming methods demand custom tools and fixtures for each part, lengthy setup times, and skilled operators who are increasingly hard to find.

To stay competitive in high-cost labor markets, they need forming equipment that keeps up — systems that switch instantly between part variants, expand design possibilities, maintain accuracy, and produce complex shapes without tooling or workforce bottlenecks.

AutoShape combines cutting, forming, engraving, and automated quality assessment into a single patented laser platform.

Laser executes all processes, where an integrated scanner ensures accuracy and generates complete digital quality records for every part — a groundbreaking step toward flexible, tool-free, fully automated production.

Our Technology

Laser Cutting

Laser cutting uses localized heat to achieve precise and flexible cutting.

Laser Forming

Laser forming applies temperature differences in the material which causes localized forming.

Laser Engraving

Add product information for traceability on every part.

Discover the Difference

-

Eliminate custom tooling and fixtures — produce any part without mechanical setup or hardware changes. Instead, time to “Laser On” from making your CAD model is less than 10 minutes.

-

Reduce manual handling and overhead, and streamline the workflows with a fully digital, automated forming process.

-

Simply upload a CAD file and load a sheet of metal — the system is fully plug-and-play. Our software automatically extracts all required data and instructs the machine to produce the part with minimal operator input.

-

Form shapes and geometries that are difficult or impossible with traditional processes — all from a single flexible platform.

-

An integrated laser scanner verifies every part and generates complete digital quality records — ensuring traceability, compliance, and trust.

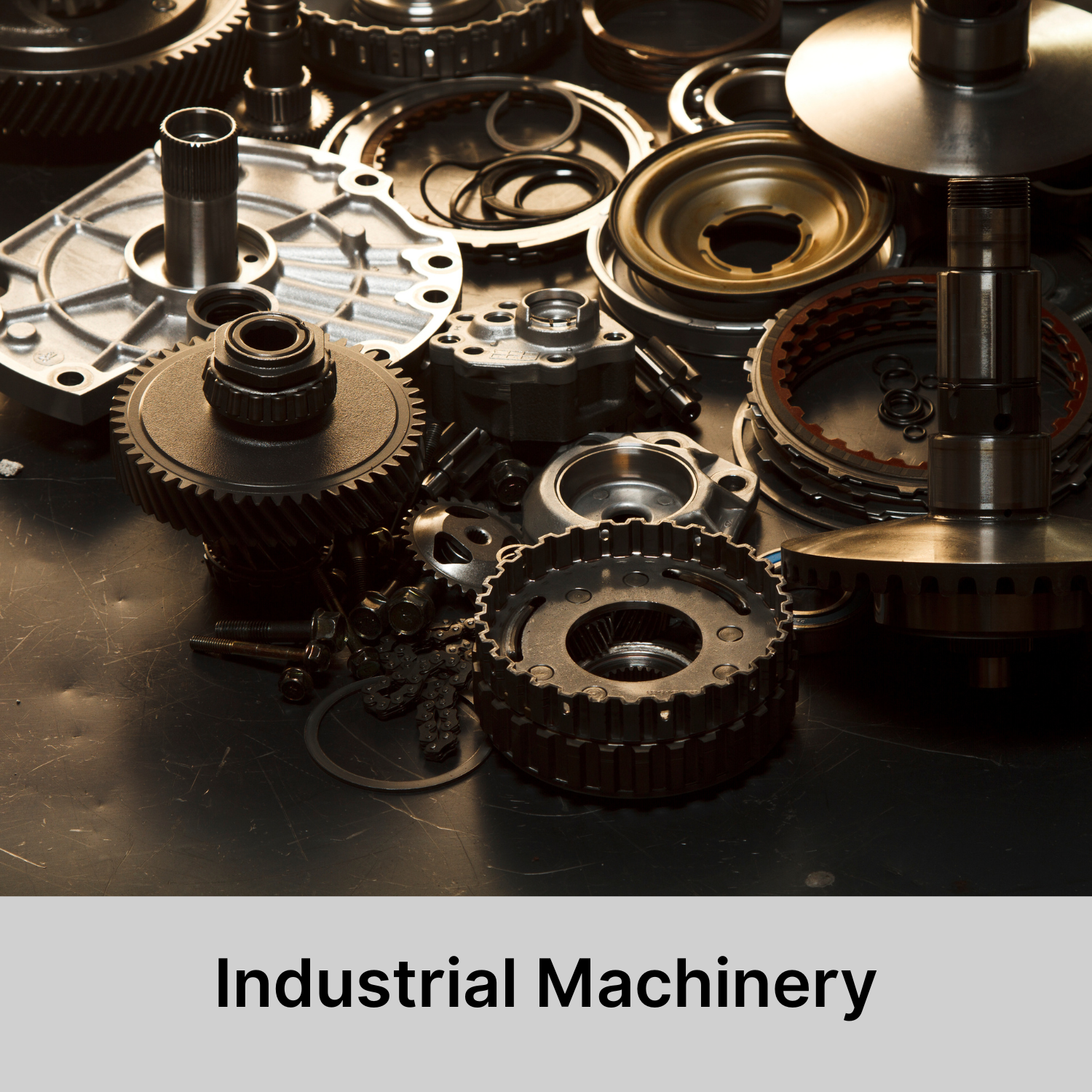

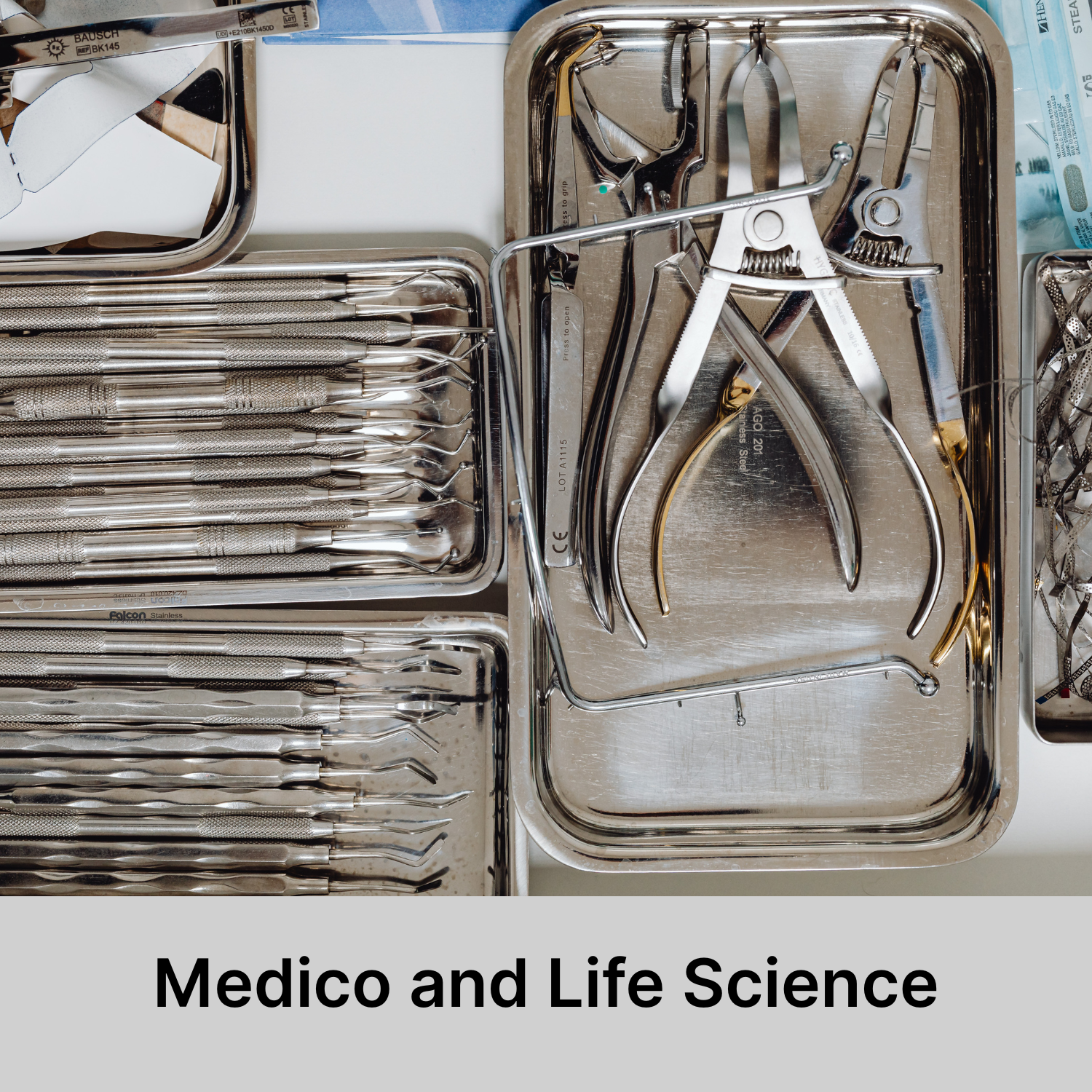

Application

AutoShape develops machines that enable flexible and automated production of sheet-metal components across a wide range of industries.

Become a Pilot Partner

AutoShape is pioneering a new class of laser forming that unifies multiple processes into one automated platform.

Our pilot program offers exclusive early access to this breakthrough capability and allows selected partners to collaborate directly with our engineering team to validate new workflows, unlock advanced geometries, and strengthen operational performance.

Partner with us to advance smarter, cleaner, and more resilient production across Europe.

Early Access for Selected Industry Leaders