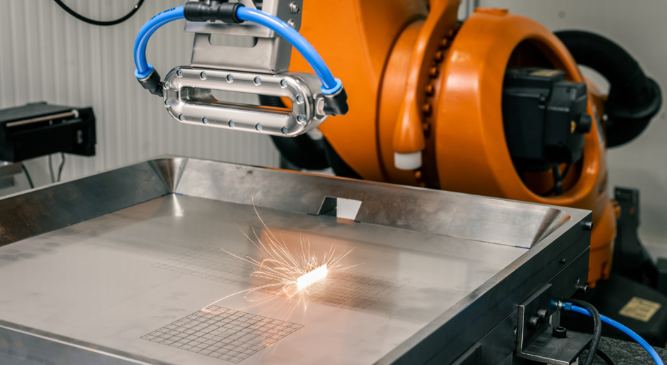

Shaping new possibilities of laser processing

AutoShape develops and implements advanced laser automation solutions for the metal industry to eliminate tooling costs and enhance efficiency, precision, and safety in manufacturing processes.

The plate manufacturing industry faces several significant challenges when it comes to sustainable and efficient manufacturing. Achieving high precision and consistency in cutting, bending, and forming sheet metal is crucial but challenging, especially with varying material properties and thicknesses.

Furthermore, having a flexible manufacturing process enabling customization, prototyping and production of small quantities to meet customer requirements is a difficult task in the industry, as it often requires several machines, customized tools, and expensive manual labor.

Finally, quality control combined with production efficiency, while minimizing waste, are nearly impossible factors to balance all at once. Ensuring every plate of sheet metal meets the stringent quality standards of the industry involves rigorous inspection processes, which can be both time-consuming and prone to human error and, thus, trip up the production efficiency.

Thus, solving these challenges is essential for manufacturers to maintain competitiveness, ensure product quality, and optimize production costs. AutoShape is on a mission to address these exact, widespread challenges.